R-Values alone do not accurately predict real-world performance

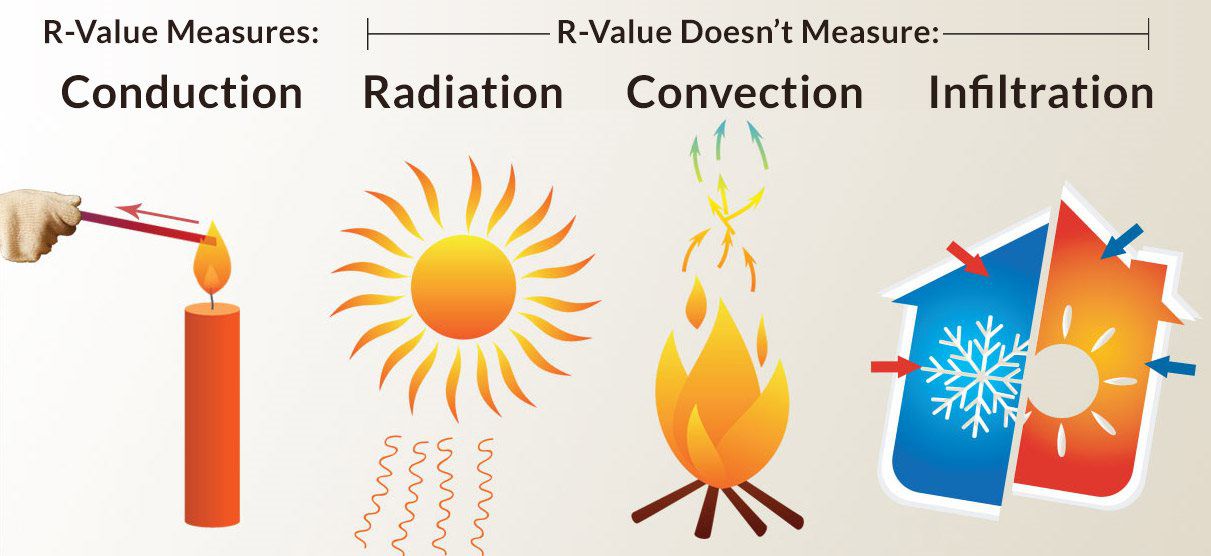

Here is why SPF and EPS foam are far superior to other forms of insulation (especially fiberglass batt) even with equivalent R-Values. Performance predictions using heat transfer calculations based on tested and published R-values alone do not accurately predict real-world performance. R-Value is a term given to the property of any material to “resist” the conduction of heat. R-Value as a metric of measurement is legitimate. The functional design of the laboratory determination of this property, relative to insulation materials, is flawed at a fundamental level – yielding what can be called the R-Value myth. This flaw forces the engineering community, bound to adhere to the scientific formulas dictated by their governing body (ASHRAE), to calculate heat loads using the “myth” that this R-Value property of various insulation materials derived by flawed test methods can accurately predict the performance of the insulation material in real life. Not true.

Let’s look at the flawed test criteria used in the laboratories to determine R-values. The first flaw relates to “standard temperature”. This stipulates that the test be conducted at a constant temperature of 75-degrees Fahrenheit. Does it seem odd that a test to determine the performance values for insulation materials for HVAC equipment would be designed around a 75-degree temperature? Who uses heating or cooling when it’s 75 degrees? It isn’t surprising that fiberglass performs well at 75-degrees. However, the efficiency of fiberglass dramatically decreases at temperatures that are above or below 75-degrees while EPS foam insulation performs very well and its efficiency increases the colder it gets.

The second flaw of the test criteria requires that R-value testing not start until the materials reach what is called “steady state”. Steady state occurs when a material is exposed to a heat source and allowed to become thermally saturated so that for every single unit of heat entering on one side of the material and then exits the opposite side. This seems very scientific. It appears logical, but it misses a single important issue relevant to predicting real world performance: The amount of time it takes to reach steady state.

Why is the time to reach steady state important?

What every consumer should demand from their home or business insulation material is “high thermal inertia,” (the degree of slowness with which the insulation’s temperature reaches that of the environment). Fiberglass insulation reaches this steady state saturation point very quickly, therefore it is vastly inferior to EPS closed cell foam insulation which takes roughly an entire day to reach this saturation point.

In the final, real-world analysis, EPS foam insulation is a far better insulation material. In addition, EPS foam insulation acts as an impediment to air and moisture infiltration. Fiberglass cannot make the same claim.

To conclude… R-Value does not accurately reflect real-world performance!

It is a mistake to conclude that varying insulation materials with the same R-values perform equally well (unless you happen to live in perfect conditions where the outside temperature remains steady at 75°). Think of it this way… Would you rather pour hot coffee over your lap into a thin EPS foam cup or onto 1″ of fiberglass batt insulation? That’s easy to answer. This is precisely why products such as refrigerators and commercial coolers use rigid foam as insulation. It performs!

It is a mistake to conclude that varying insulation materials with the same R-values perform equally well (unless you happen to live in perfect conditions where the outside temperature remains steady at 75°). Think of it this way… Would you rather pour hot coffee over your lap into a thin EPS foam cup or onto 1″ of fiberglass batt insulation? That’s easy to answer. This is precisely why products such as refrigerators and commercial coolers use rigid foam as insulation. It performs!

SPRAY FOAM ATTICS NEVER GET MORE THAN 4 TO 6 DEGREES HOTTER OR COLDER THAN THE TEMPERATURE INSIDE THE STRUCTURE

It’s Wise to CONSIDER THE VALUE OF CONDITIONED ATTIC STORAGE

Foam insulated attics are clean, temperature and humidity controlled, dry storage space. Most of all it frees up valuable living space down below. Convert any garage or attic area into conditioned storage space.

- Significantly Reduced Utility Costs

- Fast Installation

- High Wind Resistance

- Very Little Job Site Material Waste

- Exceptional Strength Characteristics

- Consistent Quality